How We Transformed a Distillery Floor with Advanced Epoxy and Polyurethane Coatings

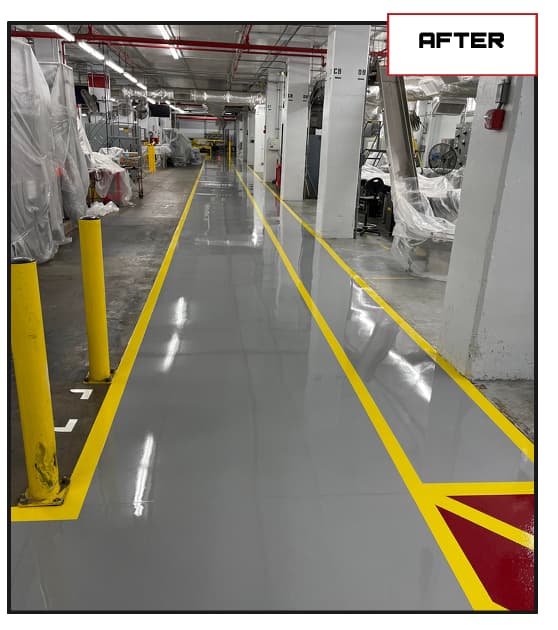

We recently had the opportunity to apply Gulf Coast Paint’s CM-15, PC-1703, and CT-332 products on a distillery floor, and the results were exceptional. The combination of Poly-Chem PC-1703’s strong adhesion to the concrete, followed by the tough, chemical-resistant topcoat of Gulf-Thane CT-332, provided a seamless and durable surface capable of withstanding the heavy foot traffic and exposure to chemicals in the distillery environment.

The ease of application and rapid curing times allowed us to complete the job efficiently, leaving a high-gloss, easily maintained floor that significantly enhances both the safety and aesthetics of the facility.

Gulf Coast Products offers a range of specialized products designed to meet these demanding requirements. Two of their key products Chemical Mastic CM-15, Poly-Chem PC-1703, and Gulf-Thane CT-332—exemplify advanced protective technologies that are ideal for various applications.

The Poly-Chem PC-1703 is a 100% solids, low-viscosity epoxy primer specifically developed for use on concrete surfaces. It serves as a base layer under epoxy and polyurethane coatings, making it essential for heavy-duty flooring systems. Ideal for areas where solvent odors are a concern, this product meets stringent EPA regulations and provides a seamless application without thinning requirements.

The Gulf-Thane CT-332 is a clear, high-gloss, polyester polyurethane coating known for its resistance to chemicals and environmental exposure. Its durability, combined with flexibility, makes it ideal for use on decorative floors, epoxy coatings, and high-wear areas. Its non-yellowing properties ensure it maintains a clear, pristine finish, even after prolonged exposure to harsh conditions.

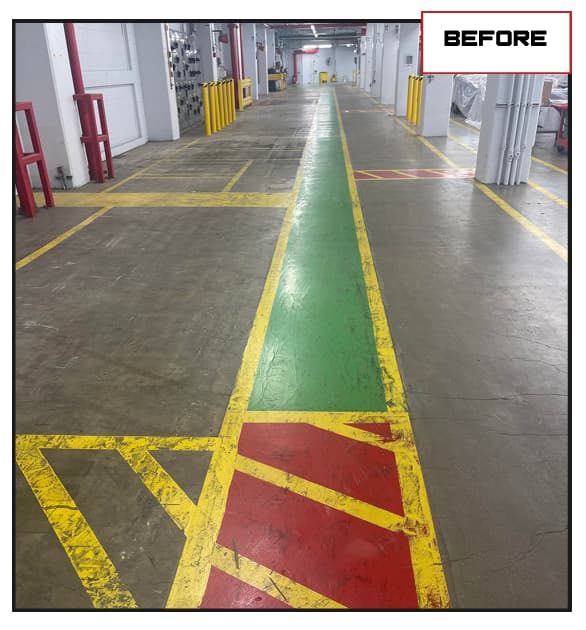

The outcome, as you can see from the above before and after photos, was more than ideal.