Cost-Effective and Efficient

In today’s industrial landscape, maximizing efficiency and minimizing downtime are top priorities for facility operators. Recently, our team had the opportunity to apply these principles while restoring stainless steel agitator blades inside a reactor tank for a major player in the power industry. This project underscores our expertise in tailored coating solutions and showcases how innovative approaches can solve complex challenges.

The Challenge

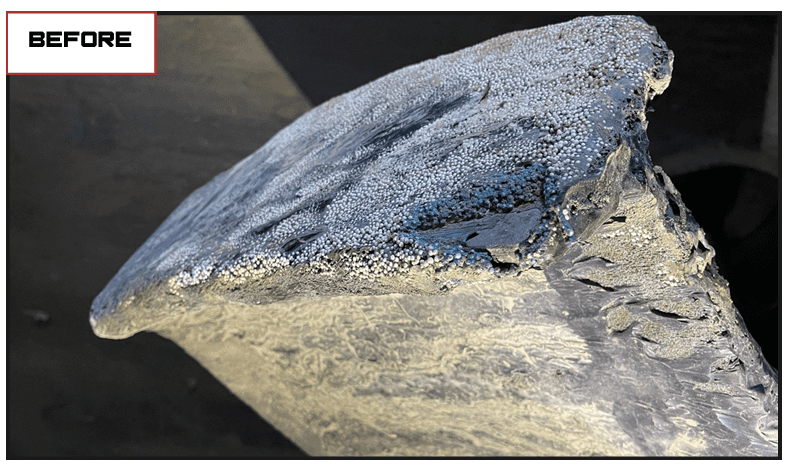

Reactor tank agitator blades endure constant exposure to abrasive slurries, leading to wear that can compromise efficiency and safety. The traditional approach—removing the blades for repair—is both costly and time-consuming. Our goal was to deliver a solution that would restore these critical components without disrupting operations.

Restoration Process Highlights:

Initial Inspection: The blades, exhibiting significant damage, were photographed to document their initial state.

Surface Preparation: The blades were sandblasted to achieve a clean and abraded surface, essential for optimal adhesion.

Rebuilding the Structure: Damaged areas were rebuilt with Duromar UltraBuild, a heavily filled carbide ceramic compound designed for high abrasion resistance. Its trowel-grade application allowed precise restoration to original contours.

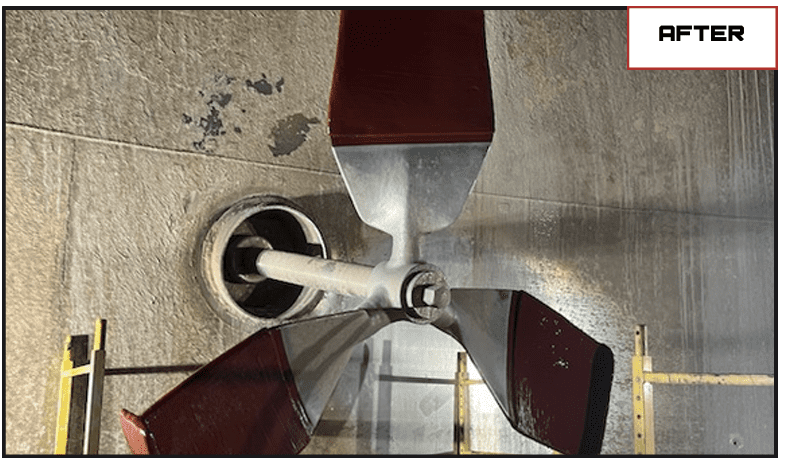

Coating Application: Two topcoat options were applied:

Gray: UltraBuild served as a robust protective layer.

Red: EAC provided enhanced chemical and abrasion resistance, tailored for the reactor’s operating conditions.

The Results

The restored blades now feature an abrasive-resistant ceramic finish designed to handle the rigors of heavy slurry service. The dual-coating system not only repaired the damage but also extended the blades’ service life. By documenting the process with photos—capturing the transformation from damaged to restored—we provided the client with a clear record of the value delivered.

What This Means for Facility Owners

Our approach to reactor tank repairs reflects a commitment to practical, cost-effective solutions. On-site restoration reduces downtime, while advanced coatings like UltraBuild and EAC ensure performance that lasts. For facility operators seeking to improve efficiency without sacrificing quality, this project demonstrates that it’s possible to meet demanding requirements while staying on schedule and budget. We’re proud to bring expertise and innovation to every challenge we tackle. Our approach to reactor tank repairs reflects a commitment to practical, cost-effective solutions.